End line refers to all the end-of-line movement processes of various machines. The END OF LINE machine sector has seen an increase in demand, from companies in different industrial sectors, who have discovered the advantages that these machines can bring when customers are looking for integration, automation, intelligent machines and 4.0 applications in industries. These material handling systems are available in many different varieties to adapt to the different products or materials that need to be transported.

Idle roller conveyors: Idle roller conveyors are the ideal and economical solution for product handling and internal logistics in every industrial sector.

Motorized transport roller conveyors: Motorized roller conveyors allow the movement of products along the entire work cycle automatically and without the use of operators. In fact, they connect the different areas of the packaging line and transport the loads individually, at predetermined speeds, allowing a continuous and constant cycle.

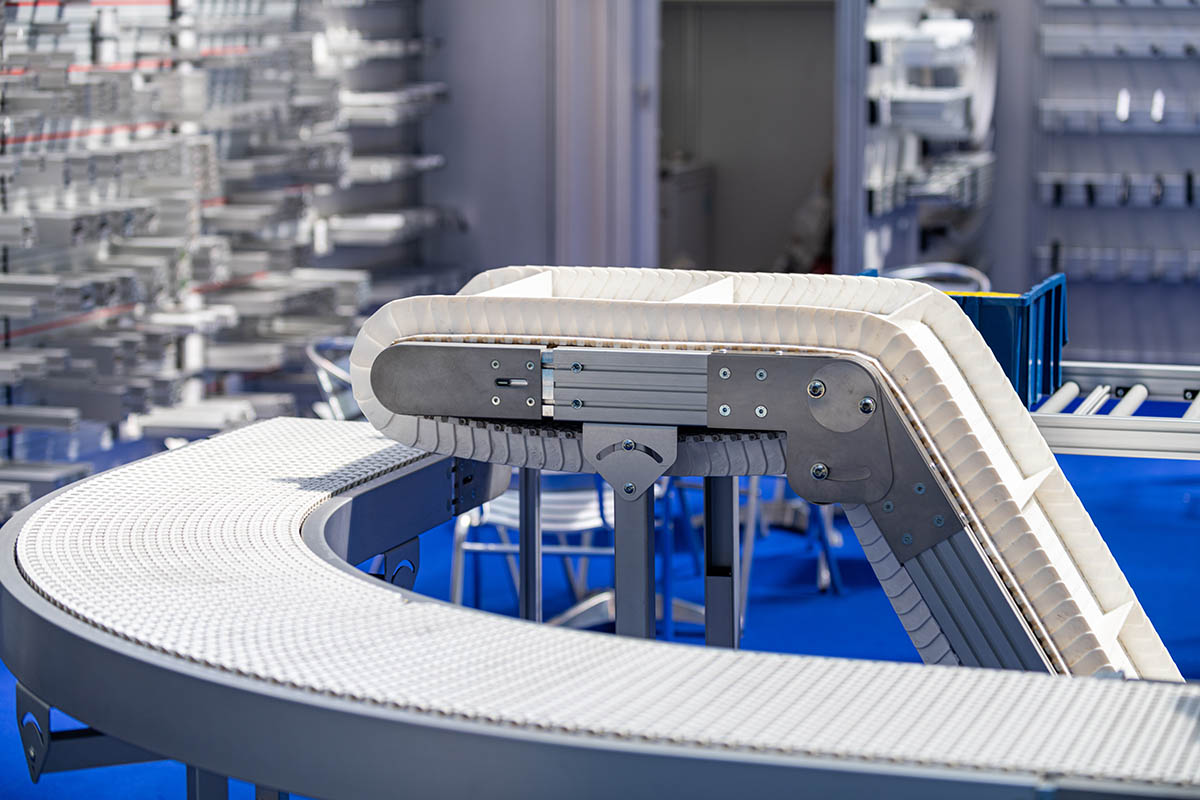

Belt conveyors with belt: The belt keeps the position of the objects stable. The pace, direction, curvature and dimensions of the conveyor belt vary according to the customer’s needs.

Plastic and metal mesh: The belt is selected based on the properties of the transported product to obtain maximum product flow with minimum product loss. PSE understands your needs and suggests the best product for your application.

Pneumatic/mechanical translation systems: Pneumatics are particularly suitable for the movement and holding of parts and tools for machinery and industrial processes. Pneumatic systems are used to obtain the movement or rotation of a gripping device of moving parts during a production process.